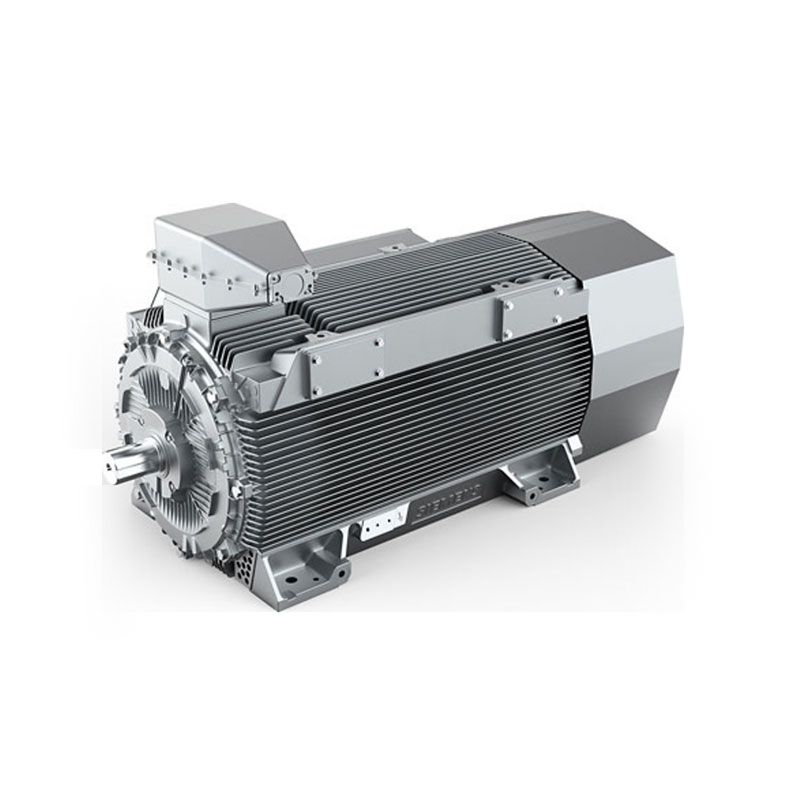

INNOMOTICS HV C Air-Cooled

INNOMOTICS HV C air-cooled is the new ultracompact, extremely reliable high-voltage motor and trans-standard motor for applications in safe areas (where there is no risk of explosion) – as well as a hazardous Zones 2 and 22 with types of protection Ex ec and Ex tc.

The real highlight is the revolutionary cooling concept, which is used for all air-cooled versions of this platform. Fin cooling, tube cooling and an internal cooling circuit are smartly combined, and in conjunction with the vibration-optimized, rugged enclosure design, ensure a long service life and reliability – even when operating under extreme conditions. They have a very low noise level and have a unique power density with approximately 10 - 15% higher power output from the same frame size. The innovative design concept ensures maximum flexibility when it comes to integrating the drives in plants and systems – and also reduces the cabling costs.

Another plus point is that now all compact, air-cooled high-voltage motors and trans-standard motors – whether with or without explosion protection – now share a standard platform.

The associated standard construction and handling principles reduce costs over the complete lifecycle: extending from planning and procurement through engineering and plant/system integration up to service, storage and spare part management.

But there's more: Using the optional INNOMOTICS CONNECT 600 connector box, Innomotics HV C can be integrated into the digital SIDRIVE IQ platform. This facilitates Cloud-based analysis of the status data, therefore allowing the drive system to be subsequently optimized.

Technical Data

| Power range: | Up to 2 MW |

| Shaft heights: | 355 – 560 mm |

| Number of poles: | 2 – 8 |

| Rated voltage: | 2 – 11 kV |

| Degree of protection: | IP55 – IP66 |

| Cooling method: | IC411, IC416v |

| Operating mode: | VSD / DOL |

| Explosion protection: | Ex ec, Ex tc |

Features

- Cooling system that combines the inner cooling circuit with tube cooling

- Extremely high power density that sets standards in the market

- Improved cooling – where hotspots are reliably avoided

- Vibration-optimized design of the motor mounting feet

- Very compact, service-optimized terminal box – same design for 6 kV and 11 kV – with a multitude of possible positions

- Cable routing inside the motor

- Very short delivery times with high on-time delivery

- Data Matrix Code for fast, simple access to individual motor data from mobile devices

- Status data can be analyzed via SIDRIVE IQ as well as digital service concepts – also Cloud-based

Your Advantages

- Less space required and simpler integration into plants and systems as a result of the extremely compact design

- Extremely high power density that sets standards in the market

- Extremely long lifetime as a result of the optimized temperature distribution

- Minimized noise levels reduce noise attenuation measures/costs

- Low weight simplifies handling and transport

- Extremely low vibration operation ensures a long plant/system lifetime

- Increased flexibility in plants and systems and simplified installation as a result of the variable terminal box position

- Better protection for cabling

- Accelerated project execution for fast time-to-market

- Maximum plant & system transparency and boosted productivity by integrating into digital system concepts using SIDRIVE IQ